Xbar Chart

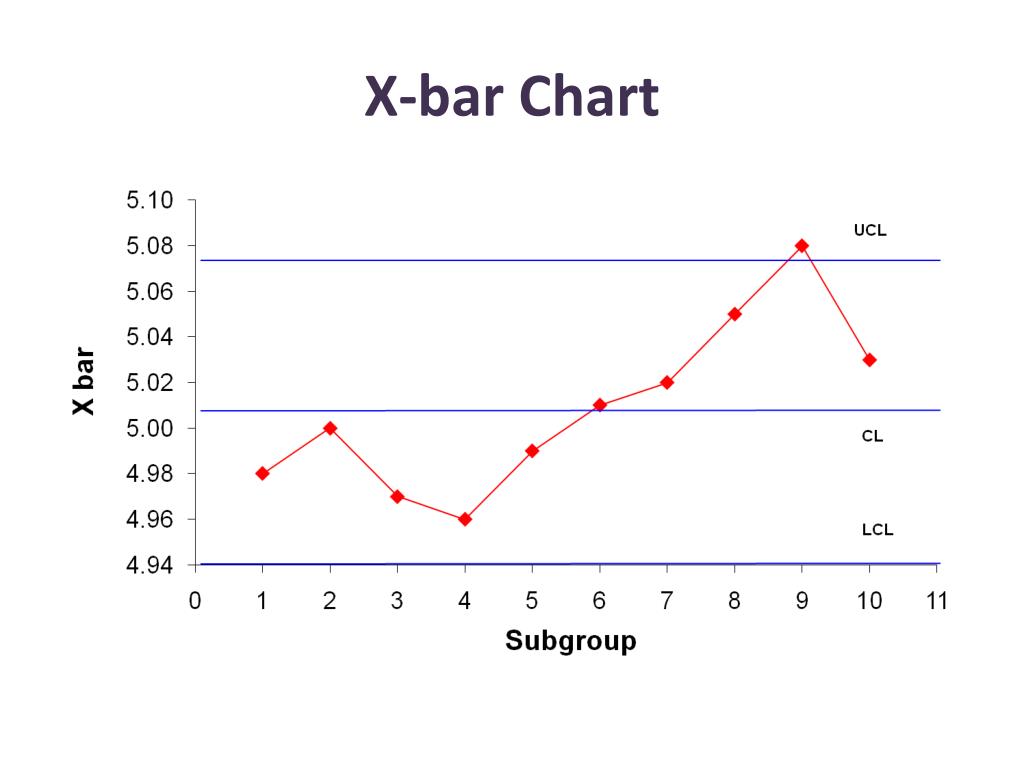

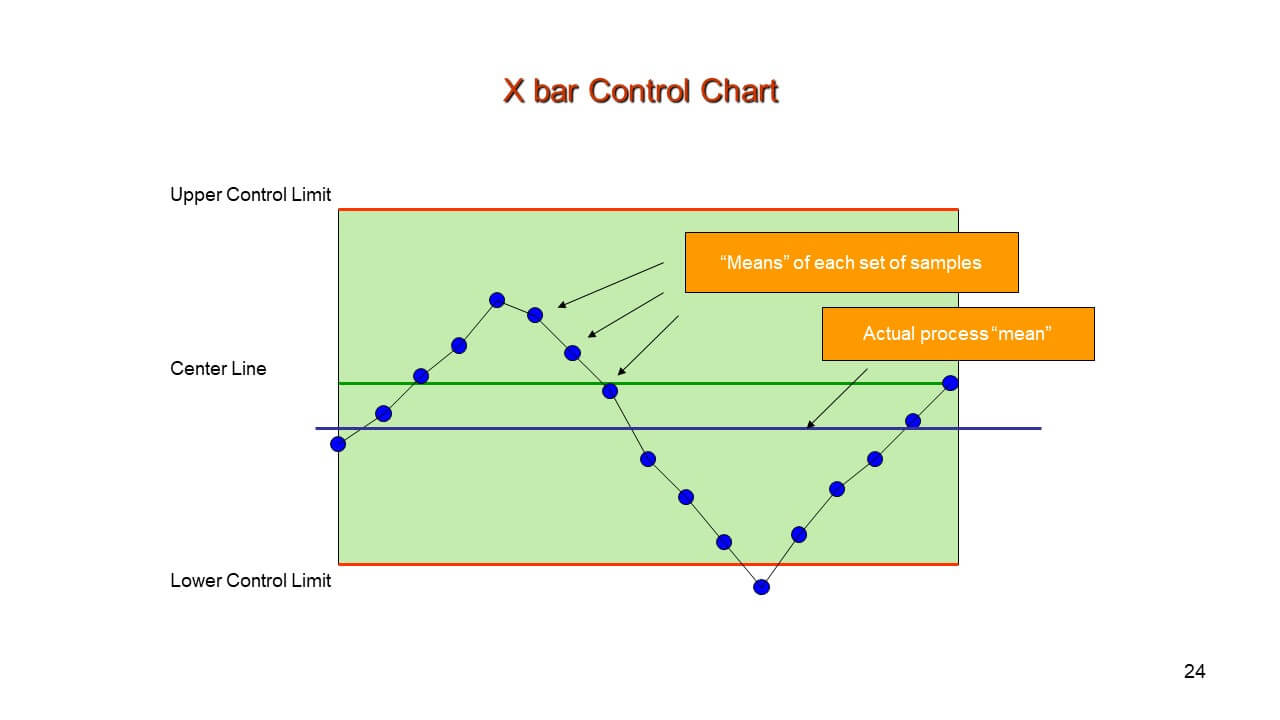

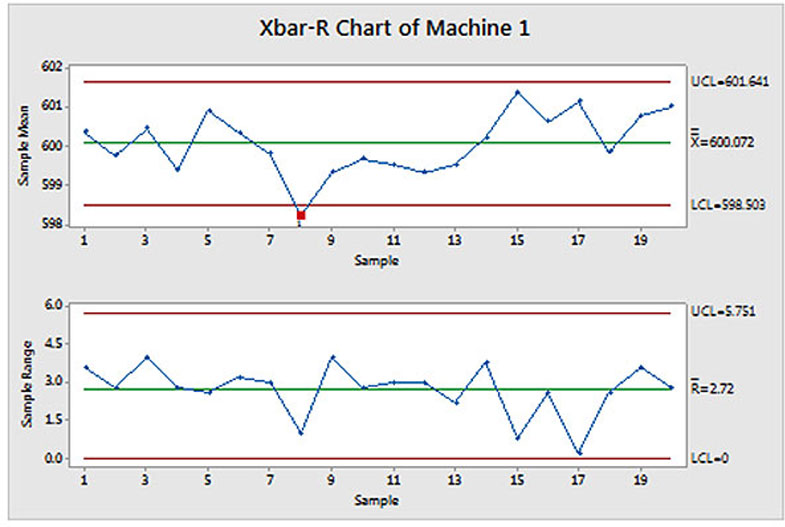

Xbar Chart - The xbar chart displays the average or mean of a sample of measurements taken from the process at regular intervals. Each point on the chart represents the average of a sample, and. Once you decide to monitor a process and after you determine using an ¯x x & r chart is appropriate, you have to construct the charts. X bar r charts are widely used control charts for variable data to examine process stability in many industries (e.g., hospital patients’ blood pressure over. What are x bar r control charts? In statistical process control (spc), the and r chart, also known as an averages and range chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of. Xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. They provide continuous data to determine how well a process functions and stays within. Together, they provide valuable insights into the process performance,. This is not difficult and by following the 8 steps. In statistical process control (spc), the and r chart, also known as an averages and range chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of. They provide continuous data to determine how well a process functions and stays within. Each point on the chart represents the average of a sample, and. Once you decide to monitor a process and after you determine using an ¯x x & r chart is appropriate, you have to construct the charts. Together, they provide valuable insights into the process performance,. The xbar chart displays the average or mean of a sample of measurements taken from the process at regular intervals. Xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. X bar r charts are widely used control charts for variable data to examine process stability in many industries (e.g., hospital patients’ blood pressure over. This is not difficult and by following the 8 steps. Some of the run rules are based on the concept of zones: In statistical process control (spc), the and r chart, also known as an averages and range chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of. Some of the run rules are based on the concept of zones: Together, they provide valuable insights into the process performance,. This is not difficult. They provide continuous data to determine how well a process functions and stays within. Each point on the chart represents the average of a sample, and. Together, they provide valuable insights into the process performance,. Some of the run rules are based on the concept of zones: In statistical process control (spc), the and r chart, also known as an. They provide continuous data to determine how well a process functions and stays within. Some of the run rules are based on the concept of zones: Once you decide to monitor a process and after you determine using an ¯x x & r chart is appropriate, you have to construct the charts. What are x bar r control charts? X. Together, they provide valuable insights into the process performance,. X bar r charts are widely used control charts for variable data to examine process stability in many industries (e.g., hospital patients’ blood pressure over. Each point on the chart represents the average of a sample, and. In statistical process control (spc), the and r chart, also known as an averages. Together, they provide valuable insights into the process performance,. They provide continuous data to determine how well a process functions and stays within. This is not difficult and by following the 8 steps. In statistical process control (spc), the and r chart, also known as an averages and range chart is a type of scheme, popularly known as control chart,. X bar r charts are widely used control charts for variable data to examine process stability in many industries (e.g., hospital patients’ blood pressure over. Together, they provide valuable insights into the process performance,. Each point on the chart represents the average of a sample, and. This is not difficult and by following the 8 steps. In statistical process control. Xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. Once you decide to monitor a process and after you determine using an ¯x x & r chart is appropriate, you have to construct the charts. X bar r charts are widely used control charts for variable data. Some of the run rules are based on the concept of zones: Once you decide to monitor a process and after you determine using an ¯x x & r chart is appropriate, you have to construct the charts. What are x bar r control charts? Xbar r charts are often used collectively to plot the process mean (xbar) and process. Together, they provide valuable insights into the process performance,. The xbar chart displays the average or mean of a sample of measurements taken from the process at regular intervals. Some of the run rules are based on the concept of zones: They provide continuous data to determine how well a process functions and stays within. What are x bar r. In statistical process control (spc), the and r chart, also known as an averages and range chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of. Together, they provide valuable insights into the process performance,. Some of the run rules are based on the concept of zones: X bar r charts. They provide continuous data to determine how well a process functions and stays within. Together, they provide valuable insights into the process performance,. Each point on the chart represents the average of a sample, and. Some of the run rules are based on the concept of zones: Xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. In statistical process control (spc), the and r chart, also known as an averages and range chart is a type of scheme, popularly known as control chart, used to monitor the mean and range of. The xbar chart displays the average or mean of a sample of measurements taken from the process at regular intervals. This is not difficult and by following the 8 steps.Chapter 12 Managing Production Operations ppt video online download

PPT Xbar and R charts PowerPoint Presentation, free download ID1379085

PPT STATISTICAL PROCESS CONTROL AND QUALITY MANAGEMENT PowerPoint Presentation ID3363131

X bar r chart in excel ArwenAbubakar

X Bar R Chart Example

XBar and RChart Understanding the Difference

Control Chart 101 Definition, Purpose and How to EdrawMax Online

Xbar R Control Chart Quality Gurus

Control Limits for xbar r chart show out of control conditions Smarter Solutions, Inc.

Difference Between XBar and RChart and How They Are Used ROP

Once You Decide To Monitor A Process And After You Determine Using An ¯X X & R Chart Is Appropriate, You Have To Construct The Charts.

X Bar R Charts Are Widely Used Control Charts For Variable Data To Examine Process Stability In Many Industries (E.g., Hospital Patients’ Blood Pressure Over.

What Are X Bar R Control Charts?

Related Post: