Tpu Hardness Chart

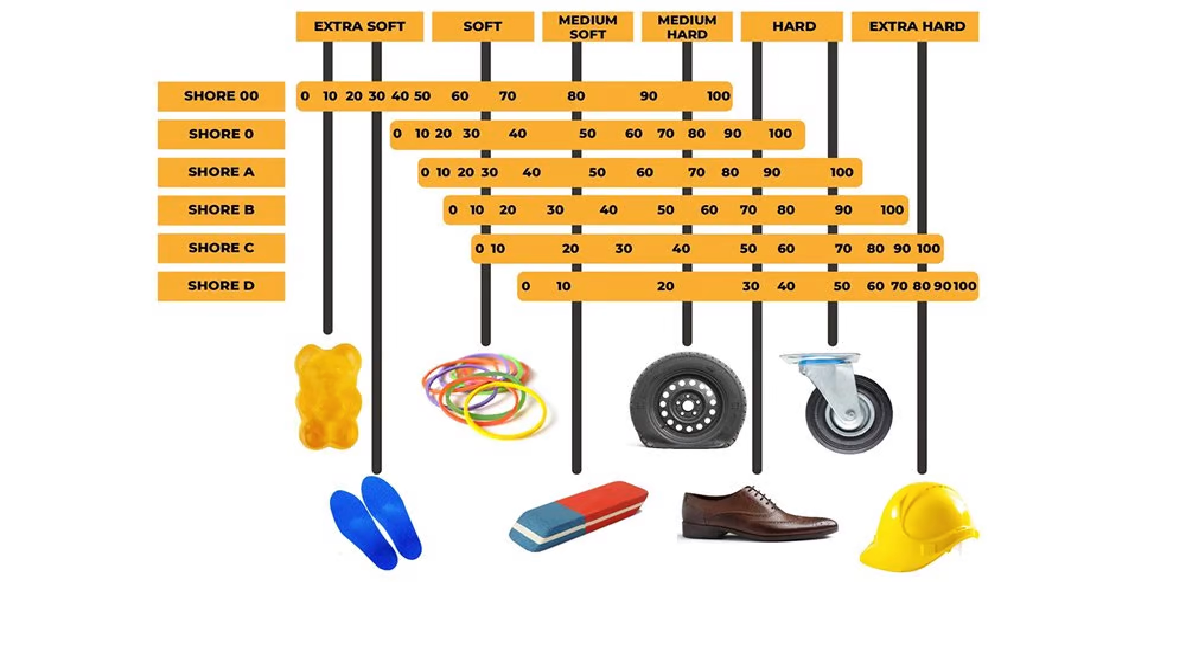

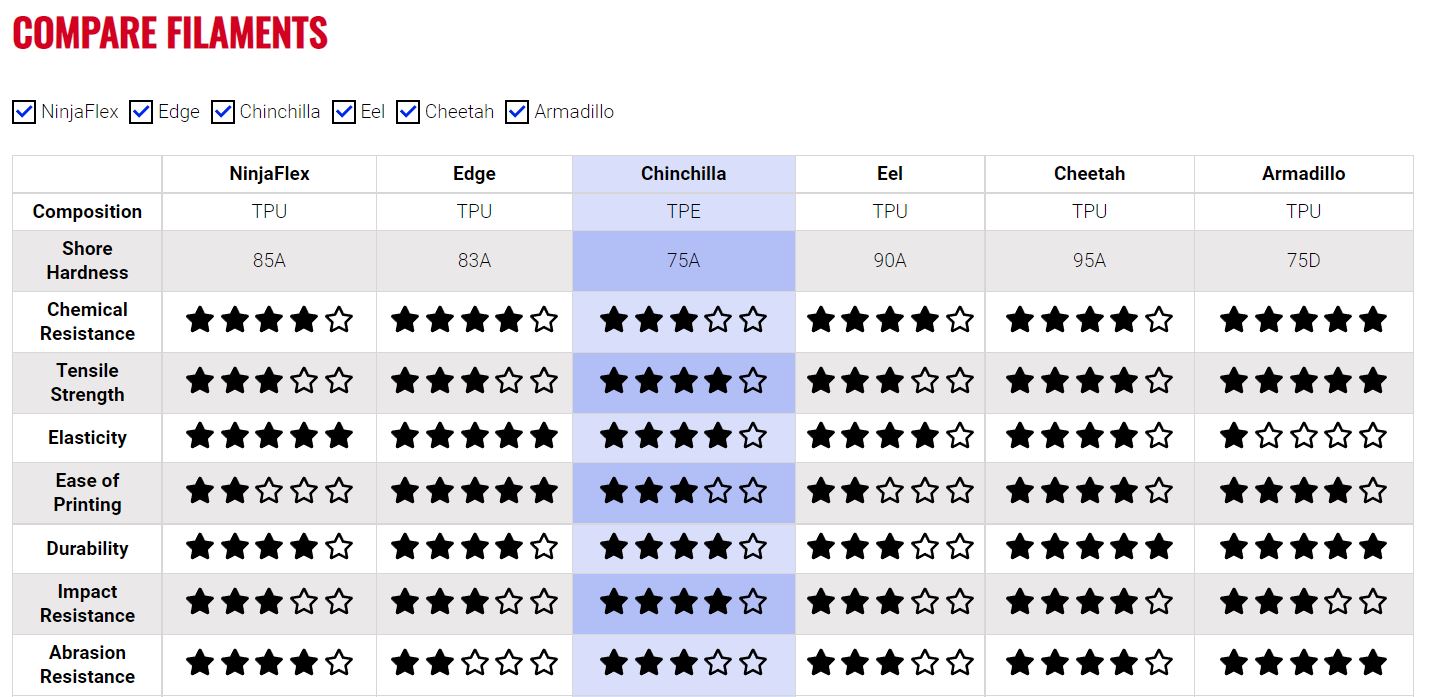

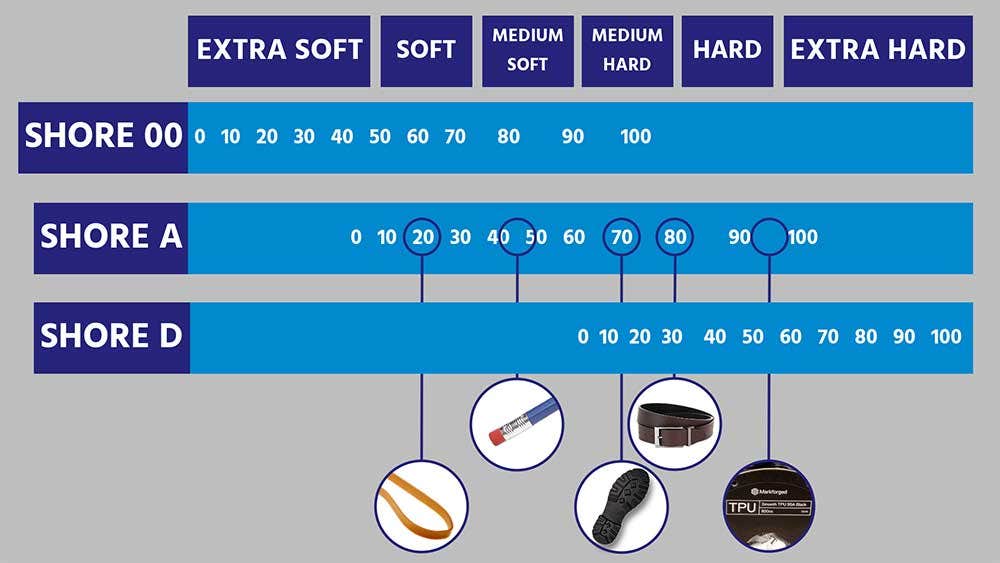

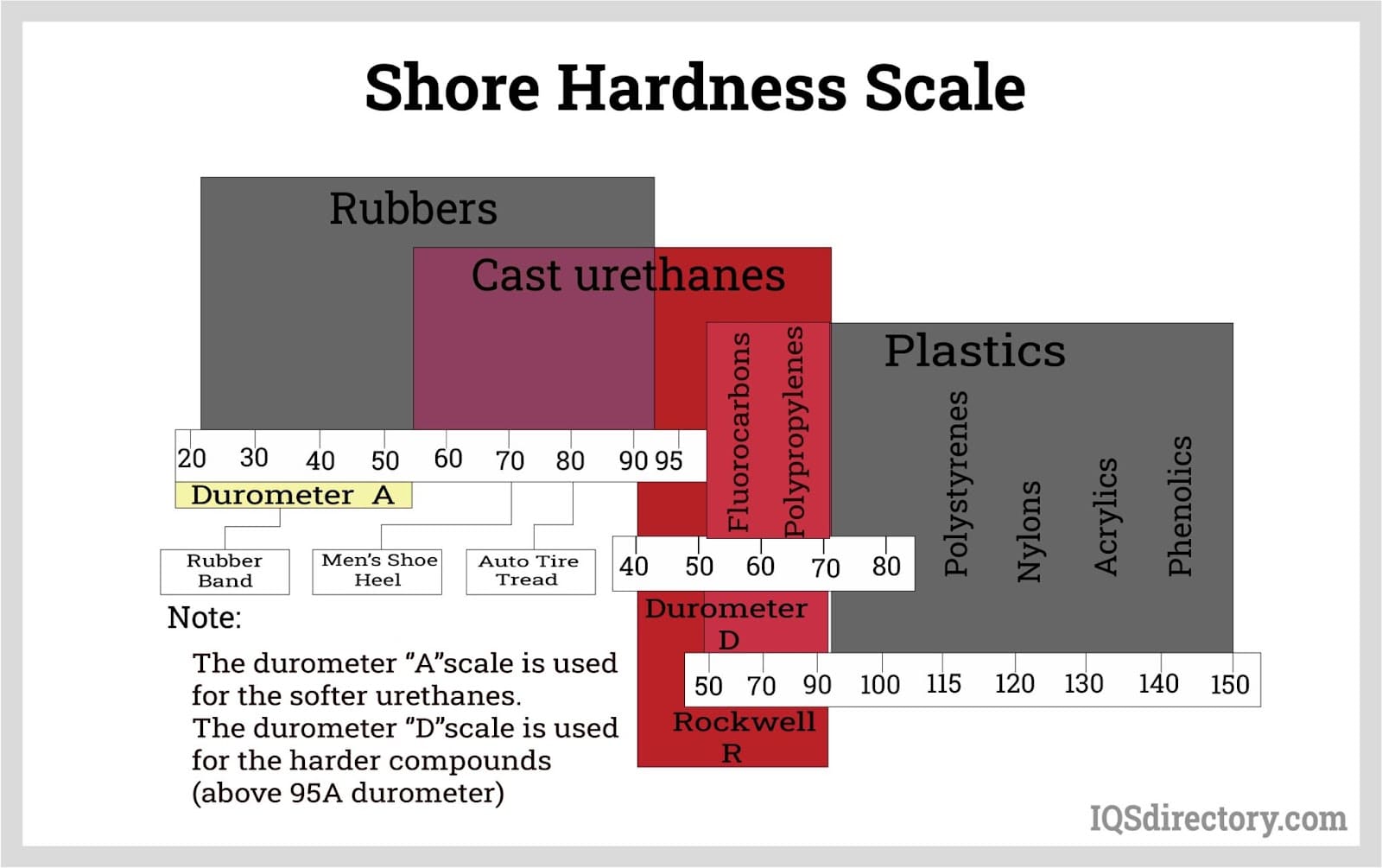

Tpu Hardness Chart - Tpu stands for thermoplastic polyurethane. Tpu is the ideal polymer for applications in a wide variety of markets, including footwear, wire and cable, film and sheet, compounding, adhesives and specialty molded parts. Tacoma power offers 0% interest loans for up to five years to help you. It’s known for its durability, flexibility, and high tensile strength,. Most polyurethane is made into foam, such as kitchen sponges. The hard segments form physical crosslinks, while. Thermoplastic polyurethane (tpu) is a thermoplastic elastomer that is commonly used in injection molding and 3d printing. Tpu is a specific type of tpe, consisting of hard and soft segments derived from isocyanates, polyols, and chain extenders. Unlike traditional polyurethane, which can be rigid or. Although tpu is made from a variety of materials, products made from tpu generally have elasticity, transparency, and low. Tpu or thermoplastic polyurethane, represents a class of plastics synthesized through a polyaddition reaction involving a diisocyanate and one or more diols. The individual components required to produce a tpu are:. Tpu, or thermoplastic polyurethane, is a versatile material that combines the best properties of both plastics and rubbers. Thermoplastic polyurethane (tpu) is a thermoplastic elastomer that is commonly used in injection molding and 3d printing. Unlike traditional polyurethane, which can be rigid or. It represents a class of polyurethanes that possess thermoplastic properties. Tacoma power offers 0% interest loans for up to five years to help you. Tpu stands for thermoplastic polyurethane. It’s known for its durability, flexibility, and high tensile strength,. Most polyurethane is made into foam, such as kitchen sponges. It represents a class of polyurethanes that possess thermoplastic properties. Thermoplastic polyurethane, commonly referred to as tpu, is a versatile type of plastic often used in a wide range of applications due to its unique set of properties. Tpu stands for thermoplastic polyurethane. Tpu, or thermoplastic polyurethane, is a versatile material that combines the best properties of both plastics and. Tpu stands for thermoplastic polyurethane. Tpu is a specific type of tpe, consisting of hard and soft segments derived from isocyanates, polyols, and chain extenders. Tpu, or thermoplastic polyurethane, is a versatile material that combines the best properties of both plastics and rubbers. Thermoplastic polyurethane, commonly referred to as tpu, is a versatile type of plastic often used in a. The hard segments form physical crosslinks, while. Tpu is a specific type of tpe, consisting of hard and soft segments derived from isocyanates, polyols, and chain extenders. It’s known for its durability, flexibility, and high tensile strength,. Tpu, or thermoplastic polyurethane, is a versatile material that combines the best properties of both plastics and rubbers. Thermoplastic polyurethane (tpu) is a. Tpu, or thermoplastic polyurethane, is a versatile material that combines the best properties of both plastics and rubbers. Tpu or thermoplastic polyurethane, represents a class of plastics synthesized through a polyaddition reaction involving a diisocyanate and one or more diols. It represents a class of polyurethanes that possess thermoplastic properties. It’s known for its durability, flexibility, and high tensile strength,.. Tpu stands for thermoplastic polyurethane. Thermoplastic polyurethane (tpu) is a thermoplastic elastomer that is commonly used in injection molding and 3d printing. Although tpu is made from a variety of materials, products made from tpu generally have elasticity, transparency, and low. Tpu is the ideal polymer for applications in a wide variety of markets, including footwear, wire and cable, film. It’s known for its durability, flexibility, and high tensile strength,. Tpu is a specific type of tpe, consisting of hard and soft segments derived from isocyanates, polyols, and chain extenders. The individual components required to produce a tpu are:. The hard segments form physical crosslinks, while. Tacoma power offers 0% interest loans for up to five years to help you. The individual components required to produce a tpu are:. Tpu is a specific type of tpe, consisting of hard and soft segments derived from isocyanates, polyols, and chain extenders. Tacoma power offers 0% interest loans for up to five years to help you. Thermoplastic polyurethane, commonly referred to as tpu, is a versatile type of plastic often used in a. Thermoplastic polyurethane, commonly referred to as tpu, is a versatile type of plastic often used in a wide range of applications due to its unique set of properties. Tpu or thermoplastic polyurethane, represents a class of plastics synthesized through a polyaddition reaction involving a diisocyanate and one or more diols. The individual components required to produce a tpu are:. Although. It’s known for its durability, flexibility, and high tensile strength,. Tpu, or thermoplastic polyurethane, is a versatile material that combines the best properties of both plastics and rubbers. Thermoplastic polyurethane, commonly referred to as tpu, is a versatile type of plastic often used in a wide range of applications due to its unique set of properties. Tpu is a specific. The hard segments form physical crosslinks, while. Thermoplastic polyurethane, commonly referred to as tpu, is a versatile type of plastic often used in a wide range of applications due to its unique set of properties. The individual components required to produce a tpu are:. Thermoplastic polyurethane (tpu) is a thermoplastic elastomer that is commonly used in injection molding and 3d. It’s known for its durability, flexibility, and high tensile strength,. Tpu is the ideal polymer for applications in a wide variety of markets, including footwear, wire and cable, film and sheet, compounding, adhesives and specialty molded parts. Tpu is a specific type of tpe, consisting of hard and soft segments derived from isocyanates, polyols, and chain extenders. Tpu or thermoplastic polyurethane, represents a class of plastics synthesized through a polyaddition reaction involving a diisocyanate and one or more diols. Unlike traditional polyurethane, which can be rigid or. It represents a class of polyurethanes that possess thermoplastic properties. Tacoma power offers 0% interest loans for up to five years to help you. Thermoplastic polyurethane (tpu) is a thermoplastic elastomer that is commonly used in injection molding and 3d printing. Most polyurethane is made into foam, such as kitchen sponges. Tpu stands for thermoplastic polyurethane. Thermoplastic polyurethane, commonly referred to as tpu, is a versatile type of plastic often used in a wide range of applications due to its unique set of properties. Tpu, or thermoplastic polyurethane, is a versatile material that combines the best properties of both plastics and rubbers.TPU 3D Filament, Shore Hardness Comparison

TPU 3D Filament, Shore Hardness Comparison

Testing colorFabb varioShore TPU Foaming 3D printing filament — CNC Kitchen

TPE&TPU 3dprinting materials

Shore A hardness values of TPU and composites. Download Table

Testing colorFabb varioShore TPU Foaming 3D printing filament — CNC Kitchen

Durometer and Shore Hardness Explained Swift Supplies

Brings Elastomers to Composite 3D Printers With TPU 95A Launch

Tpu Hardness Chart D Vs A factflow

Advantages and Properties of Polyurethane

The Individual Components Required To Produce A Tpu Are:.

Although Tpu Is Made From A Variety Of Materials, Products Made From Tpu Generally Have Elasticity, Transparency, And Low.

The Hard Segments Form Physical Crosslinks, While.

Related Post: