Surface Finish Chart

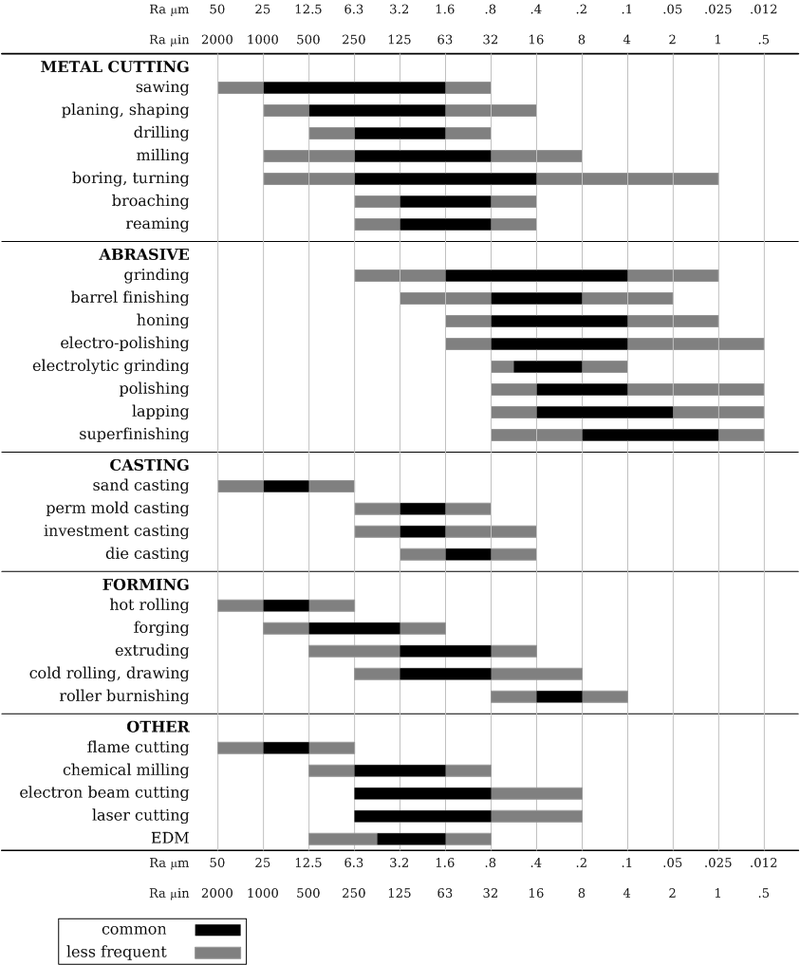

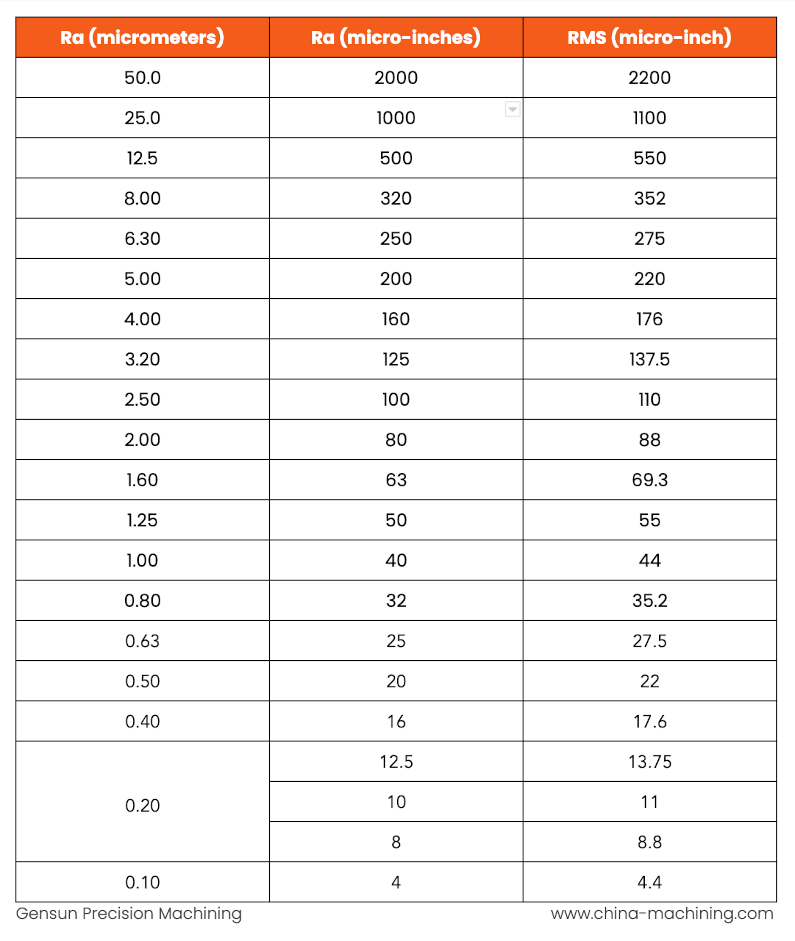

Surface Finish Chart - The following charts and tables convert surface finish or roughness between selected industry standard units. If you make things with a machine, design things, or just want to. Machining surface finish influences the quality, durability and performance of manufactured parts and components. Includes symbols, abbreviations, and practical examples. By understanding terms like ra, rz, and rms, machinists can achieve the desired surface finish to enhance product performance, aesthetics, and function. Surface finish charts are used to depict the average roughness profile of a certain material after different processing techniques i.e., grinding, polishing and buffing. A chart can look complex and confusing, but it shows important data that you can use to improve the surface finish. For instance, when manufactured products possess smooth surfaces, they. Aside from dimensions and tolerances, another important callout is surface finish. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Surface finish charts are used to depict the average roughness profile of a certain material after different processing techniques i.e., grinding, polishing and buffing. Learn what surface finish means, how to measure it, and how to read a surface roughness chart. Here are some reasons why surface. For instance, when manufactured products possess smooth surfaces, they. Have you come across a surface finishing chart? We’ll look at how to measure surface roughness, understand the numbers like ra, and use a surface roughness chart. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. This will help designers and manufacturers select surface. Machining surface finish influences the quality, durability and performance of manufactured parts and components. If you make things with a machine, design things, or just want to. Here are some reasons why surface. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. By understanding terms like ra, rz, and rms, machinists can achieve the desired surface finish to enhance product performance, aesthetics, and function. The following charts. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. The following charts and tables convert surface finish or roughness between selected industry standard units. A chart can look complex and confusing, but it shows important data that you can use to improve the surface finish. Surface finish is essential in product design because. If you make things with a machine, design things, or just want to. Here are some reasons why surface. The following charts and tables convert surface finish or roughness between selected industry standard units. We’ll look at how to measure surface roughness, understand the numbers like ra, and use a surface roughness chart. By understanding terms like ra, rz, and. A chart can look complex and confusing, but it shows important data that you can use to improve the surface finish. This will help designers and manufacturers select surface. By understanding terms like ra, rz, and rms, machinists can achieve the desired surface finish to enhance product performance, aesthetics, and function. Machining surface finish influences the quality, durability and performance. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Includes symbols, abbreviations, and practical examples. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Learn what surface finish means, how to measure it, and how to read a surface roughness chart. Have you. Learn what surface finish means, how to measure it, and how to read a surface roughness chart. Have you come across a surface finishing chart? By understanding terms like ra, rz, and rms, machinists can achieve the desired surface finish to enhance product performance, aesthetics, and function. For instance, when manufactured products possess smooth surfaces, they. Surface finish charts help. Here are some reasons why surface. For instance, when manufactured products possess smooth surfaces, they. Surface finish charts are used to depict the average roughness profile of a certain material after different processing techniques i.e., grinding, polishing and buffing. Surface finish is a measure of the overall texture of a surface that is characterized by the lay,. Have you come. Aside from dimensions and tolerances, another important callout is surface finish. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Surface finish is a measure of the overall texture of a surface that is characterized by the lay,. Learn what surface finish means, how to measure it, and how to. If you make things with a machine, design things, or just want to. We’ll look at how to measure surface roughness, understand the numbers like ra, and use a surface roughness chart. For instance, when manufactured products possess smooth surfaces, they. This will help designers and manufacturers select surface. Machining surface finish influences the quality, durability and performance of manufactured. A chart can look complex and confusing, but it shows important data that you can use to improve the surface finish. Machining surface finish influences the quality, durability and performance of manufactured parts and components. Surface finish is a measure of the overall texture of a surface that is characterized by the lay,. By understanding terms like ra, rz, and. A chart can look complex and confusing, but it shows important data that you can use to improve the surface finish. Surface finish is a measure of the overall texture of a surface that is characterized by the lay,. Aside from dimensions and tolerances, another important callout is surface finish. Surface finish charts are used to depict the average roughness profile of a certain material after different processing techniques i.e., grinding, polishing and buffing. If you make things with a machine, design things, or just want to. For instance, when manufactured products possess smooth surfaces, they. Learn what surface finish means, how to measure it, and how to read a surface roughness chart. By understanding terms like ra, rz, and rms, machinists can achieve the desired surface finish to enhance product performance, aesthetics, and function. Here are some reasons why surface. Surface finish is essential in product design because it can significantly impact the parts’ performance, function, quality and aesthetics. Machining surface finish influences the quality, durability and performance of manufactured parts and components. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. This will help designers and manufacturers select surface.Surface Finish Machinng Chart PDF PDF Surface Roughness Machining

Machining surface finish chart, conversion, comparator, method, degree, Ra, Rz, RMS

EDM Surface Finish Charts Metalworking Mechanical Engineering

Surface Roughness Chart Understanding Surface Finishes RapidDirect (2023)

The Only Surface Finishing Chart (and Guide) You'll Ever Need

Surface Finish Guide 5.5" x 8.5" Tool Box CNC Shop eBay in 2023 Surface roughness

Understand the Surface Roughness Chart and Make Great Parts

Surface Finish Chart Understanding Surface Finish in Manufacturing 3Q MACHINING

Surface Roughness Chart Understanding Surface Finishes RapidDirect

Unlock the Secrets of Surface Finish Symbols [MustRead Guide!]

Have You Come Across A Surface Finishing Chart?

The Following Charts And Tables Convert Surface Finish Or Roughness Between Selected Industry Standard Units.

We’ll Look At How To Measure Surface Roughness, Understand The Numbers Like Ra, And Use A Surface Roughness Chart.

Includes Symbols, Abbreviations, And Practical Examples.

Related Post:

![Unlock the Secrets of Surface Finish Symbols [MustRead Guide!]](https://www.cnccookbook.com/wp-content/uploads/2017/08/SurfaceFinishRoughnessByProcess.jpg)