Sipoc Chart

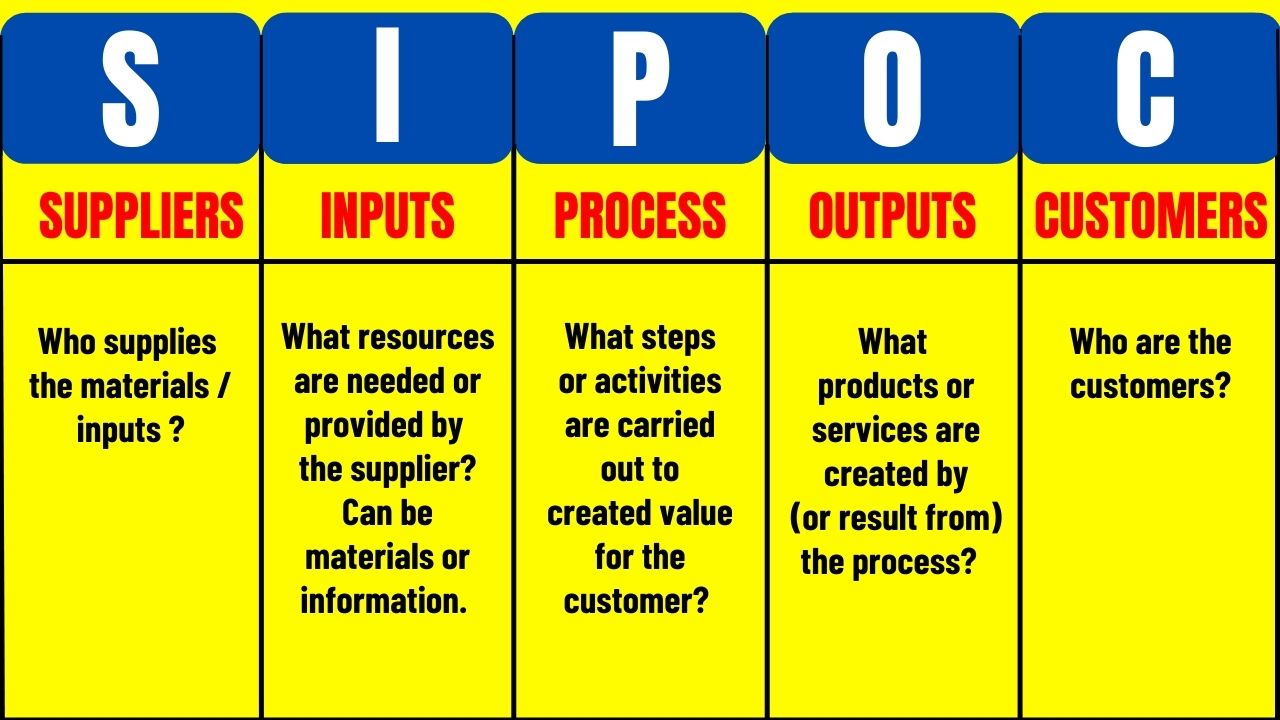

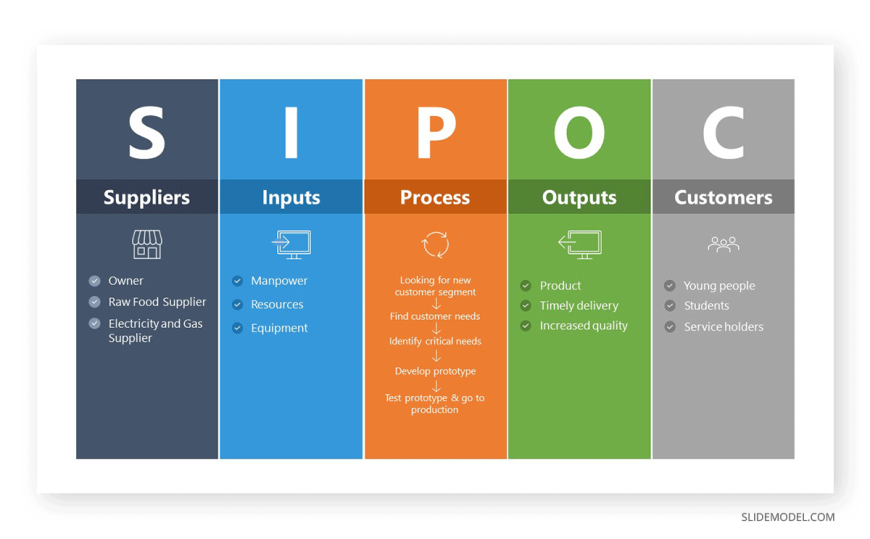

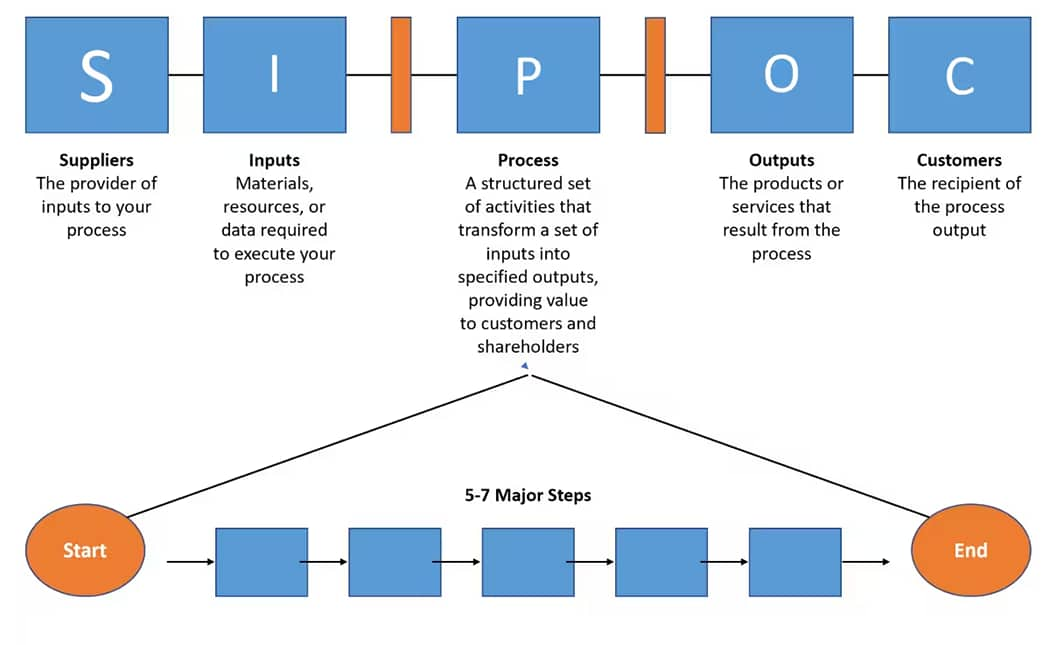

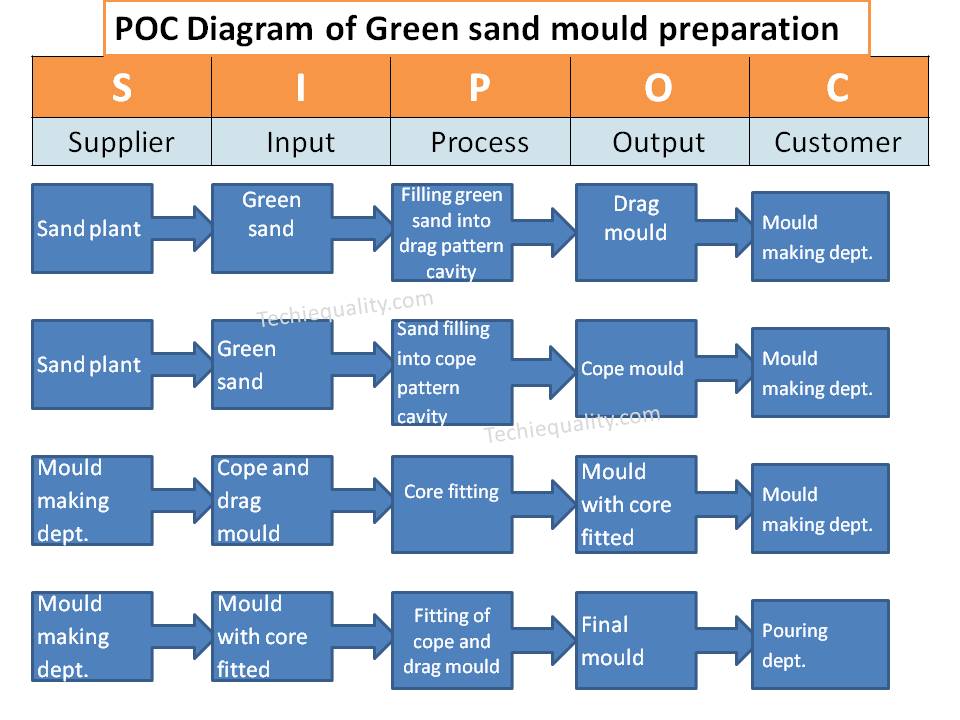

Sipoc Chart - In practical terms, sipoc is a process mapping and improvement method that. It visualizes how everyone in the process. The sipoc model allows teams to figure out how s [suppliers], i [inputs], and p [process] are impacting o [outputs] and c [customer] needs. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: A sipoc diagram will help you streamline workflows, identify and solve problems, and remove wasteful activities. It does it through process visualization with information limited to only what's. Sipoc is an acronym that stands for suppliers, inputs, process, outputs and customers. The sipoc methodology acts as a tool to identify the inputs and outputs of target. A sipoc diagram typically takes the form of a table. To clarify, sipoc is an acronym for suppliers, inputs, processes, outputs, and customers. Sipoc is an acronym that stands for suppliers, inputs, process, outputs and customers. In practical terms, sipoc is a process mapping and improvement method that. It does it through process visualization with information limited to only what's. A sipoc diagram typically takes the form of a table. Actionable insights into factors that. A powerful tool for process improvement the sipoc diagram is one of the easiest, but effective tools of process improvement which helps to map and. It visualizes how everyone in the process. The sipoc model allows teams to figure out how s [suppliers], i [inputs], and p [process] are impacting o [outputs] and c [customer] needs. A sipoc diagram will help you streamline workflows, identify and solve problems, and remove wasteful activities. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: A powerful tool for process improvement the sipoc diagram is one of the easiest, but effective tools of process improvement which helps to map and. A sipoc diagram will help you streamline workflows, identify and solve problems, and remove wasteful activities. To clarify, sipoc is an acronym for suppliers, inputs, processes, outputs, and customers. In practical terms, sipoc is a. A sipoc diagram will help you streamline workflows, identify and solve problems, and remove wasteful activities. A powerful tool for process improvement the sipoc diagram is one of the easiest, but effective tools of process improvement which helps to map and. The sipoc methodology acts as a tool to identify the inputs and outputs of target. In practical terms, sipoc. Sipoc is an acronym that stands for suppliers, inputs, process, outputs and customers. A powerful tool for process improvement the sipoc diagram is one of the easiest, but effective tools of process improvement which helps to map and. Actionable insights into factors that. The sipoc methodology acts as a tool to identify the inputs and outputs of target. It does. A powerful tool for process improvement the sipoc diagram is one of the easiest, but effective tools of process improvement which helps to map and. It visualizes how everyone in the process. Copis) is a tool that summarizes the inputs and outputs of one or more. A sipoc diagram will help you streamline workflows, identify and solve problems, and remove. Actionable insights into factors that. A sipoc diagram will help you streamline workflows, identify and solve problems, and remove wasteful activities. Sipoc is an acronym that stands for suppliers, inputs, process, outputs and customers. It visualizes how everyone in the process. It does it through process visualization with information limited to only what's. It does it through process visualization with information limited to only what's. To clarify, sipoc is an acronym for suppliers, inputs, processes, outputs, and customers. The sipoc methodology acts as a tool to identify the inputs and outputs of target. In practical terms, sipoc is a process mapping and improvement method that. Sipoc is an acronym that stands for suppliers,. Actionable insights into factors that. To clarify, sipoc is an acronym for suppliers, inputs, processes, outputs, and customers. The sipoc methodology acts as a tool to identify the inputs and outputs of target. The sipoc model allows teams to figure out how s [suppliers], i [inputs], and p [process] are impacting o [outputs] and c [customer] needs. Sipoc is an. It visualizes how everyone in the process. A sipoc diagram will help you streamline workflows, identify and solve problems, and remove wasteful activities. To clarify, sipoc is an acronym for suppliers, inputs, processes, outputs, and customers. A powerful tool for process improvement the sipoc diagram is one of the easiest, but effective tools of process improvement which helps to map. Copis) is a tool that summarizes the inputs and outputs of one or more. In practical terms, sipoc is a process mapping and improvement method that. To clarify, sipoc is an acronym for suppliers, inputs, processes, outputs, and customers. The sipoc model allows teams to figure out how s [suppliers], i [inputs], and p [process] are impacting o [outputs] and. The sipoc model allows teams to figure out how s [suppliers], i [inputs], and p [process] are impacting o [outputs] and c [customer] needs. It visualizes how everyone in the process. The sipoc methodology acts as a tool to identify the inputs and outputs of target. Sipoc is an acronym that stands for suppliers, inputs, process, outputs and customers. Actionable. A sipoc diagram will help you streamline workflows, identify and solve problems, and remove wasteful activities. It visualizes how everyone in the process. Actionable insights into factors that. A sipoc diagram typically takes the form of a table. In process improvement, sipoc or suppliers, inputs, process, outputs and customers (sometimes in the reversed order: The sipoc model allows teams to figure out how s [suppliers], i [inputs], and p [process] are impacting o [outputs] and c [customer] needs. Copis) is a tool that summarizes the inputs and outputs of one or more. Sipoc is an acronym that stands for suppliers, inputs, process, outputs and customers. In practical terms, sipoc is a process mapping and improvement method that. The sipoc methodology acts as a tool to identify the inputs and outputs of target.Sipoc Model

What is SIPOC diagram? Understand with example

11_howtomakeasipocdiagramcustomers SlideModel

Sipoc Diagram Template

SIPOC diagram What it is & how to create one MindManager

Sipoc Chart Template

Sipoc diagram process mapping Artofit

SIPOC Template Manufacturing Sector SIPOC Diagram Example

Sipoc Template

What Is a SIPOC Diagram and How to Implement It?

It Does It Through Process Visualization With Information Limited To Only What's.

To Clarify, Sipoc Is An Acronym For Suppliers, Inputs, Processes, Outputs, And Customers.

A Powerful Tool For Process Improvement The Sipoc Diagram Is One Of The Easiest, But Effective Tools Of Process Improvement Which Helps To Map And.

Related Post: