Finish Chart

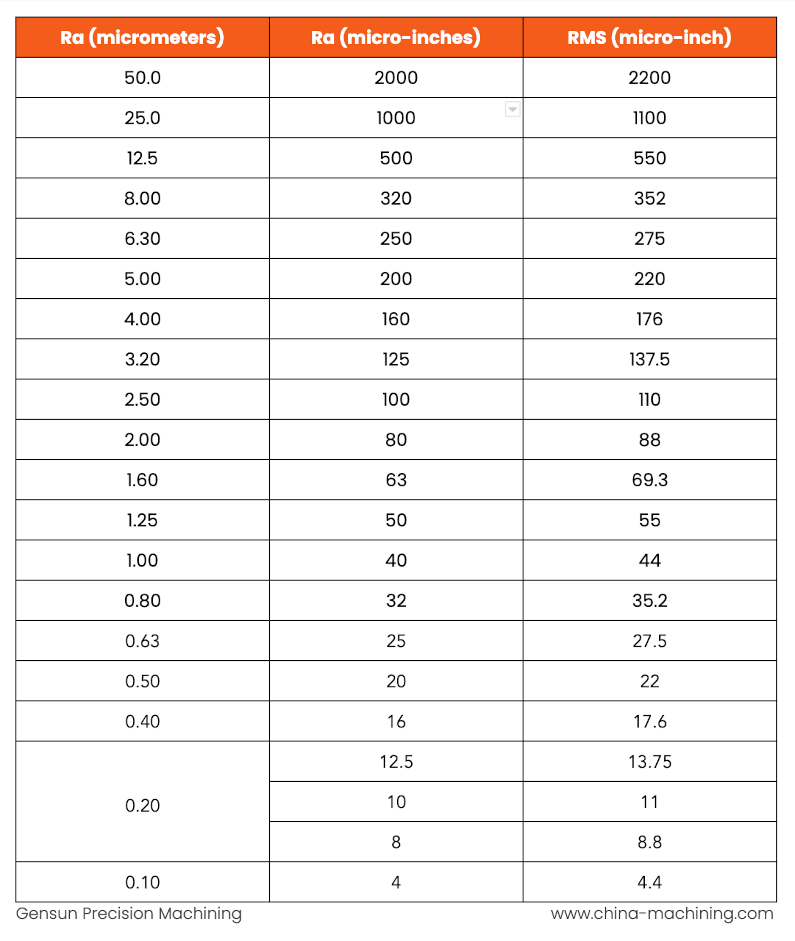

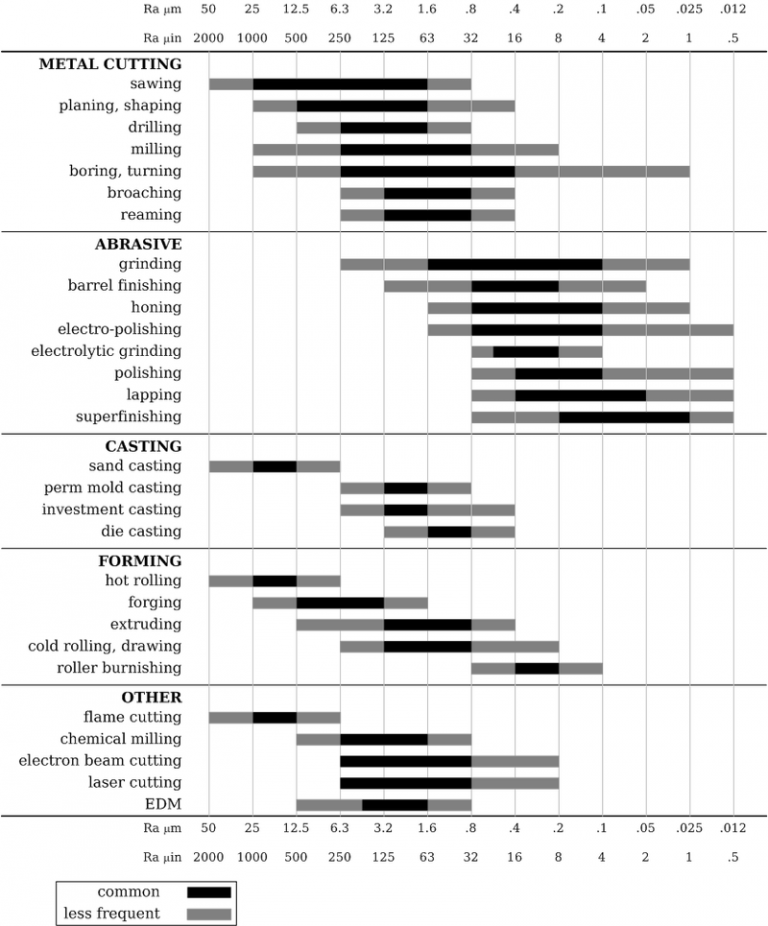

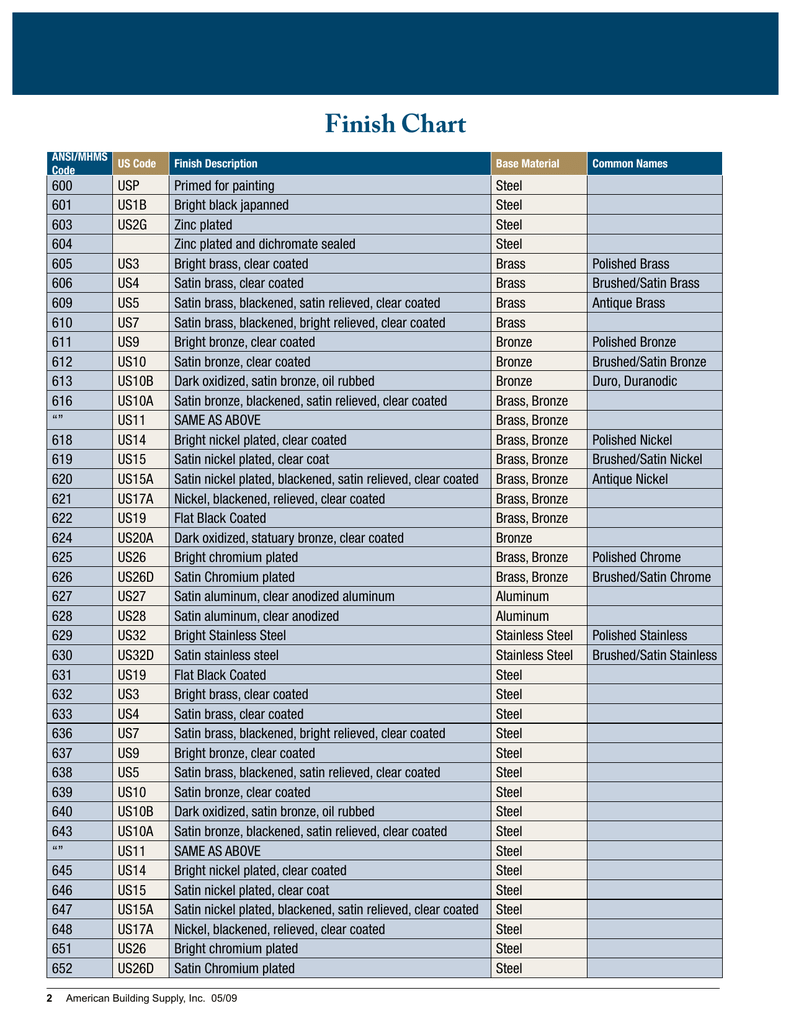

Finish Chart - This will help designers and manufacturers select surface. There are a variety of considerations, and they. By better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and performance of. How do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? The following charts and tables convert surface finish or roughness between selected industry standard units. The following chart lists some of the common finishes found on locking hardware and components. Limited to three symbols per key. The table below converts surface finish or. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. It’s a practical tool for. There are a variety of considerations, and they. It’s a practical tool for. Surface finish symbols are graphical callouts to indicate surface texture and surface roughness for design parts manufactured by various manufacturing processes. By better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and performance of. The following charts and tables convert surface finish or roughness between selected industry standard units. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. How do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? Visual key codes (vkc) can be stamped on any cut key for an additional $1.00 net cost per key. A surface roughness chart is a helpful tool for understanding the relationships between different surface finishes, their corresponding roughness values, and the machining. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. A surface roughness chart is a helpful tool for understanding the relationships between different surface finishes, their corresponding roughness values, and the machining. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. This will help designers. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. It’s a practical tool for. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. There are a variety of considerations, and they. Surface finish symbols are graphical callouts to indicate surface texture and surface roughness for. Visual key codes (vkc) can be stamped on any cut key for an additional $1.00 net cost per key. The first column indicates the bhma finish code, the second column represents. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. How do product designers decide what surface finishes to require, and how should. A surface roughness chart is a helpful tool for understanding the relationships between different surface finishes, their corresponding roughness values, and the machining. It’s a practical tool for. This will help designers and manufacturers select surface. The following charts and tables convert surface finish or roughness between selected industry standard units. How do product designers decide what surface finishes to. Limited to three symbols per key. Visual key codes (vkc) can be stamped on any cut key for an additional $1.00 net cost per key. There are a variety of considerations, and they. The following charts and tables convert surface finish or roughness between selected industry standard units. The following chart lists some of the common finishes found on locking. It’s a practical tool for. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. Visual key codes (vkc) can be stamped on any cut key for an additional $1.00 net cost per key. Limited to three symbols per key. Surface finish symbols are graphical callouts to indicate surface texture and surface roughness for. How do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? The table below converts surface finish or. A surface roughness chart is a helpful tool for understanding the relationships between different surface finishes, their corresponding roughness values, and the machining. Visual key codes (vkc) can be stamped on any cut key. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes. It’s a practical tool for. By better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and performance of. The first column indicates the bhma finish code, the second column represents.. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. The first column indicates the bhma finish code, the second column represents. How do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? By better understanding the different machined surface finishes, the varying roughness levels and. There are a variety of considerations, and they. Limited to three symbols per key. Visual key codes (vkc) can be stamped on any cut key for an additional $1.00 net cost per key. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. By better understanding the different machined surface finishes, the varying roughness. The following chart lists some of the common finishes found on locking hardware and components. Surface finish charts help to understand materials’ surface parameters effectively, be it smooth or rough surfaces. This will help designers and manufacturers select surface. The following charts and tables convert surface finish or roughness between selected industry standard units. The table below converts surface finish or. A surface roughness chart is a helpful tool for understanding the relationships between different surface finishes, their corresponding roughness values, and the machining. Visual key codes (vkc) can be stamped on any cut key for an additional $1.00 net cost per key. The first column indicates the bhma finish code, the second column represents. It’s a practical tool for. How do product designers decide what surface finishes to require, and how should cnc machinists think about surface finishes? By better understanding the different machined surface finishes, the varying roughness levels and how surface finishes impact function, you can ensure the quality and performance of. Additionally, manufacturers can use the surface finish conversion chart to compare different roughness scales for manufacturing processes.Complete Surface Finish Chart, Symbols Roughness Conversion

Finish Chart American Building Supply, Inc.

Surface Roughness Chart Understanding Surface Finishes RapidDirect

Surface Finish Chart A Guide to Understanding Surface Finishing Chart

Surface Roughness Chart By Process at Patrick Oalararua blog

Surface Roughness Chart Understanding Surface Finishes RapidDirect

Unlock the Secrets of Surface Finish Symbols [MustRead Guide!]

Understand the Surface Roughness Chart and Make Great Parts

Surface Finish Chart A Guide to Understanding Surface Finishing Chart

The Only Surface Finishing Chart (and Guide) You'll Ever Need

Limited To Three Symbols Per Key.

Surface Finish Symbols Are Graphical Callouts To Indicate Surface Texture And Surface Roughness For Design Parts Manufactured By Various Manufacturing Processes.

There Are A Variety Of Considerations, And They.

Related Post:

![Unlock the Secrets of Surface Finish Symbols [MustRead Guide!]](https://www.cnccookbook.com/wp-content/uploads/2017/08/SurfaceFinishRoughnessByProcess.jpg)