Counterbore Diameter Chart

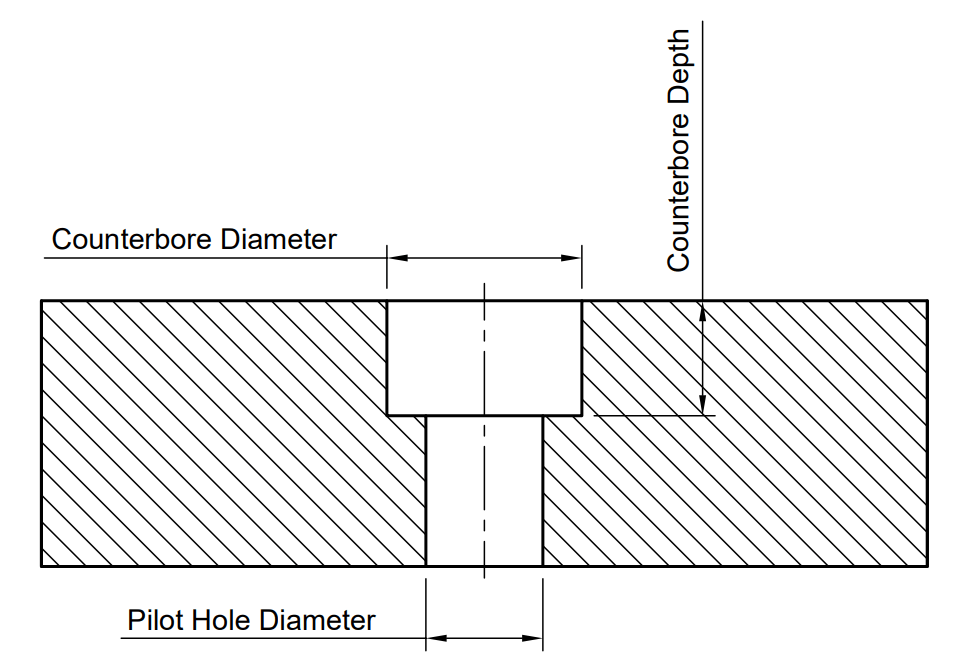

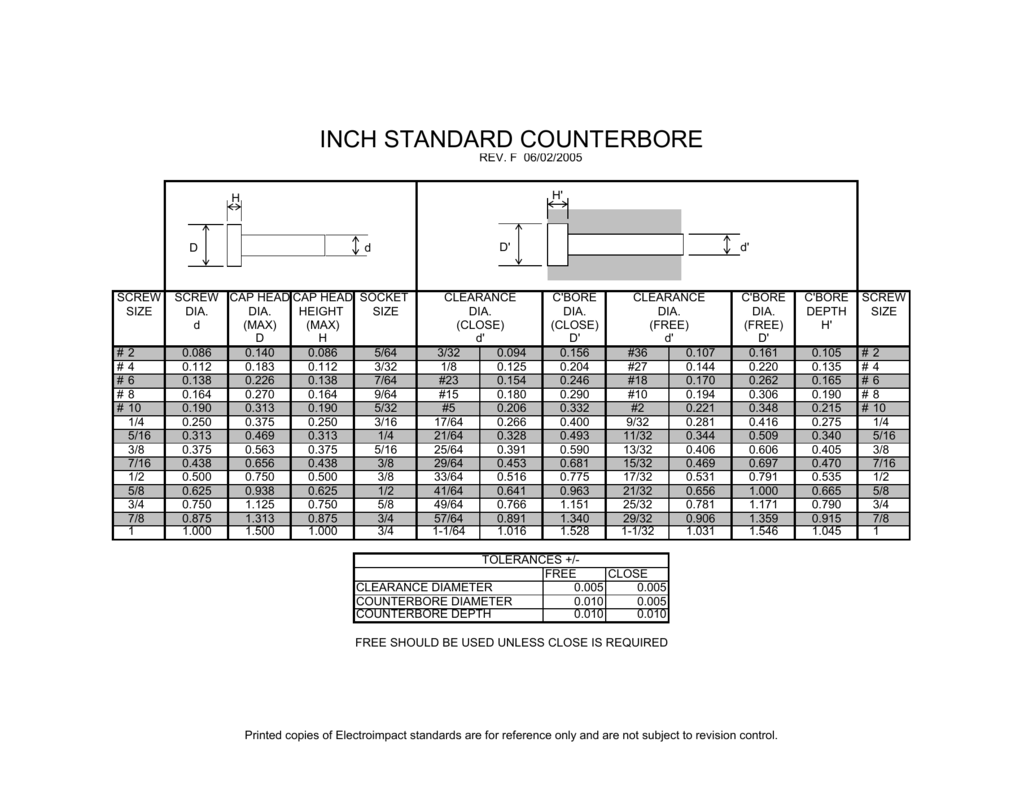

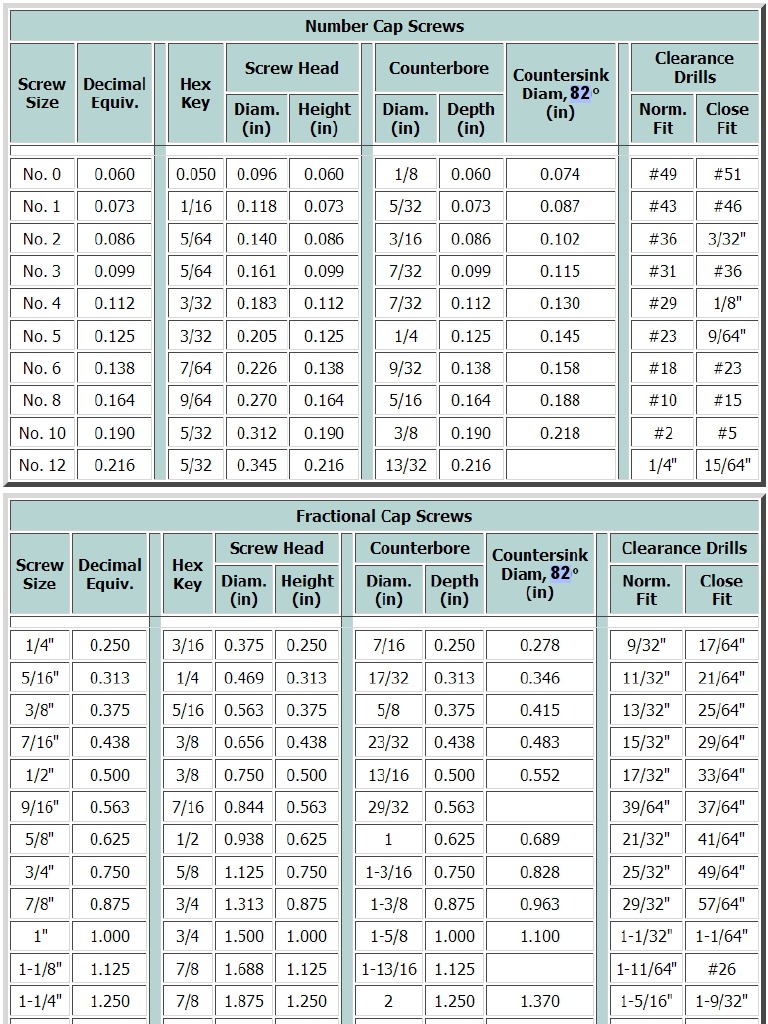

Counterbore Diameter Chart - Counterbore holes (callout symbol “⌴”) are also cylindrical and designed to increase a hole’s opening and make a flat bottom, which helps. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. What is a counterbore hole? It is used to provide a flat and recessed mounting surface for mating. Learn the differences between countersink and counterbore, their applications, how to choose the right fit for your project, and insights on thread mechanics. Counterboring is the secondary machining process of creating a cylindrical shape at the top of a hole using a counterbore. Counterbores ensure the head of a screw or bolt can sit flush with or below the surface of surrounding material. In this article, we’ll define counterbore holes, explain when to use a counterbore, and describe how to call out a counterbore hole in your designs so that it’s manufactured properly. After all, they are all meant to make screws and bolt “fit perfectly.” however,. A counterbore is a circular hole with a flat bottom which coincides with another hole. With experience machining precision components for aerospace,. After all, they are all meant to make screws and bolt “fit perfectly.” however,. Choosing the right counterbore affects assembly function, fastener accessibility, and manufacturing cost. What is a counterbore hole? Learn the differences between countersink and counterbore, their applications, how to choose the right fit for your project, and insights on thread mechanics. Counterbored holes are often used to recess socket head cap. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. In this article, we’ll define counterbore holes, explain when to use a counterbore, and describe how to call out a counterbore hole in your designs so that it’s manufactured properly. It is used to provide a flat and recessed mounting surface for mating. Counterbores ensure the head of a screw or bolt can sit flush with or below the surface of surrounding material. After all, they are all meant to make screws and bolt “fit perfectly.” however,. With experience machining precision components for aerospace,. Counterboring is the secondary machining process of creating a cylindrical shape at the top of a hole using a counterbore. Explore counterbore sizes with carr lane mfg. Counterbores ensure the head of a screw or bolt can sit flush. Counterbored holes are often used to recess socket head cap. Explore counterbore sizes with carr lane mfg. Choosing the right counterbore affects assembly function, fastener accessibility, and manufacturing cost. In this article, we’ll define counterbore holes, explain when to use a counterbore, and describe how to call out a counterbore hole in your designs so that it’s manufactured properly. Counterbores. Counterbored holes are often used to recess socket head cap. What is a counterbore hole? The counterbored section allows a bolt head or other fastener to be recessed. A counterbore is a circular hole with a flat bottom which coincides with another hole. With experience machining precision components for aerospace,. Choosing the right counterbore affects assembly function, fastener accessibility, and manufacturing cost. Explore counterbore sizes with carr lane mfg. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. Counterbores ensure the head of a screw or bolt can sit flush with or. Counterbored holes are often used to recess socket head cap. In this article, we’ll define counterbore holes, explain when to use a counterbore, and describe how to call out a counterbore hole in your designs so that it’s manufactured properly. The counterbored section allows a bolt head or other fastener to be recessed. The most noted difference between a countersink. The counterbored section allows a bolt head or other fastener to be recessed. Choosing the right counterbore affects assembly function, fastener accessibility, and manufacturing cost. A counterbore is a circular hole with a flat bottom which coincides with another hole. What is a counterbore hole? The most noted difference between a countersink and counterbore is the size and shape of. Counterbored holes are often used to recess socket head cap. It is used to provide a flat and recessed mounting surface for mating. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. In this article, we’ll define counterbore holes, explain when to. After all, they are all meant to make screws and bolt “fit perfectly.” however,. Explore counterbore sizes with carr lane mfg. With experience machining precision components for aerospace,. The counterbored section allows a bolt head or other fastener to be recessed. Counterbores ensure the head of a screw or bolt can sit flush with or below the surface of surrounding. After all, they are all meant to make screws and bolt “fit perfectly.” however,. A counterbore is a circular hole with a flat bottom which coincides with another hole. Counterboring is the secondary machining process of creating a cylindrical shape at the top of a hole using a counterbore. The most noted difference between a countersink and counterbore is the. What is a counterbore hole? The counterbored section allows a bolt head or other fastener to be recessed. Counterbore holes (callout symbol “⌴”) are also cylindrical and designed to increase a hole’s opening and make a flat bottom, which helps. With experience machining precision components for aerospace,. In this article, we’ll define counterbore holes, explain when to use a counterbore,. Counterbore holes (callout symbol “⌴”) are also cylindrical and designed to increase a hole’s opening and make a flat bottom, which helps. Learn the differences between countersink and counterbore, their applications, how to choose the right fit for your project, and insights on thread mechanics. Counterboring is the secondary machining process of creating a cylindrical shape at the top of a hole using a counterbore. With experience machining precision components for aerospace,. After all, they are all meant to make screws and bolt “fit perfectly.” however,. The counterbored section allows a bolt head or other fastener to be recessed. Explore counterbore sizes with carr lane mfg. Choosing the right counterbore affects assembly function, fastener accessibility, and manufacturing cost. In this article, we’ll define counterbore holes, explain when to use a counterbore, and describe how to call out a counterbore hole in your designs so that it’s manufactured properly. It is used to provide a flat and recessed mounting surface for mating. The most noted difference between a countersink and counterbore is the size and shape of the screw or the tool which creates the holes in the material. Counterbored holes are often used to recess socket head cap.Counterbore Hole Size for Socket Head (ANSI Metric) The Engineer's Bible

Counterbore Hole Dimensions Chart Metric at James Goldsbrough blog

Solved Give the dimensions for the counterbored holes.

Standard Counterbore Sizes at Lance Wallis blog

Metric Counterbore Hole Chart at Glenn Barbee blog

Standard Counterbore Sizes at Lance Wallis blog

Counterbore Hole Dimensions Chart Metric at James Goldsbrough blog

Counterbore Standard Sizes at Mark Connor blog

Counterbore Hole Dimensions Chart Metric at James Goldsbrough blog

Counterbore Hole Size Chart Rivet Metric Fixing

A Counterbore Is A Circular Hole With A Flat Bottom Which Coincides With Another Hole.

What Is A Counterbore Hole?

Counterbores Ensure The Head Of A Screw Or Bolt Can Sit Flush With Or Below The Surface Of Surrounding Material.

Related Post: